In-Mold Decorations: Changing Manufacturing Standards

In-Mold Decorations: Changing Manufacturing Standards

Blog Article

Understanding In-Mold Decorations: Techniques, Trends, and Ideal Practices for Optimal Results

In the world of production, the art of in-mold decors stands as a crucial aspect of product design and production. In-Mold Decorations. By delving into the methods, patterns, and finest techniques that underpin successful in-mold decor procedures, organizations can open a world of opportunities that not just elevate the visual appeal of their items but additionally simplify manufacturing efficiency and boost consumer involvement.

Product Option

Material selection is an important element of grasping in-mold designs, as it directly affects the high quality and durability of the end product. When picking products for in-mold designs, it is important to consider aspects such as compatibility with the molding procedure, the preferred visual outcome, and the environmental problems the product will encounter. Polycarbonate materials like abs, polycarbonate, and polypropylene are frequently utilized for in-mold designs because of their flexibility and capacity to accomplish elaborate layouts. These materials use outstanding moldability, enabling makers to create intricate shapes and patterns with accuracy.

In addition, products with high heat resistance are chosen for in-mold decorations, especially for products that will be exposed to elevated temperature levels during their lifecycle. By very carefully choosing the proper material for in-mold designs, makers can boost the total top quality and longevity of their items, fulfilling the assumptions of both end-users and clients - In-Mold Decorations.

Design Innovation

An important factor in advancing the area of in-mold designs is the constant exploration and implementation of design technology strategies. Style advancement plays a crucial duty in improving the aesthetic appeal, capability, and general quality of products manufactured making use of in-mold design processes. By including ingenious design elements, manufacturers can distinguish their items in the market, attract consumers, and stay in advance of competitors.

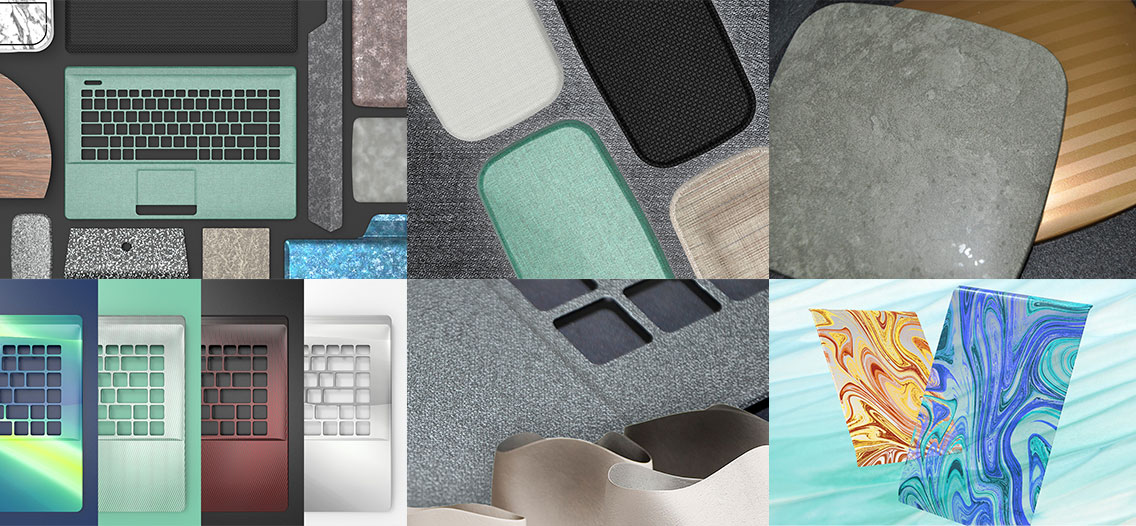

One of the crucial facets of layout innovation in in-mold designs is the combination of intricate patterns, structures, and graphics that were previously testing to attain with standard decoration approaches. Advanced innovations such as 3D printing and electronic style devices allow designers to produce complex and in-depth designs that can be effortlessly transferred onto shaped components. Additionally, making use of vibrant colors, metal finishes, and special results like gloss or matte appearances can additionally boost the visual allure of in-mold decorated items.

Additionally, layout development prolongs past aesthetic appeals to incorporate functional improvements such as ergonomic shapes, integrated attributes, and customizable elements that accommodate details individual needs. By accepting layout innovation, producers can open brand-new opportunities for personalization, product, and imagination distinction in the affordable landscape of in-mold designs.

Manufacturing Efficiency

Effective production processes are necessary for equating the ingenious layouts developed in the area of in-mold designs into top quality finished items that fulfill market needs and customer expectations. In the world of in-mold designs, production performance includes various key facets that contribute to the total success of the manufacturing process.

Automation not just increases the production process but likewise improves precision and repeatability, leading to a much more premium and uniform end product. Generally, her explanation an all natural strategy to manufacturing performance is vital in optimizing the possibility of in-mold decor methods and accomplishing ideal results in the competitive market landscape.

Top Quality Control Steps

What are the crucial techniques for making certain rigorous high quality control measures in the realm of in-mold decors? Quality control procedures are paramount in in-mold design processes to make sure the production of perfect and top quality ended up products.

Using advanced modern technologies such as automated assessment systems can also improve the top quality control process by giving reputable and exact data for analysis. These systems can identify imperfections that might be missed by hands-on assessments, thereby improving total item quality and uniformity.

Regular training and growth programs for workers associated with the in-mold decor process can likewise add to keeping high-quality requirements. By enlightening staff on best practices, high quality assumptions, and the value of focus to information, companies can promote a culture of high quality awareness throughout the company.

Customer Allure

To boost the bankability of in-mold decoration items, comprehending and catering to consumer choices play a vital function in identifying their allure and success. Offering personalization choices such as personalized designs, color variations, and textural aspects can substantially boost the charm of in-mold decoration products.

Conclusion

In-mold decorations use a efficient and flexible way to improve product go to my site looks. Grasping in-mold decorations needs a holistic approach that takes into consideration all elements of the production procedure to guarantee success.

In the realm of production, the art of in-mold decorations stands as a pivotal facet of product layout and production. Layout advancement plays a vital role in boosting the aesthetic allure, performance, and general high quality of items produced using in-mold design processes.One of the crucial aspects of layout innovation in in-mold decorations is the assimilation of intricate patterns, appearances, and graphics that were previously testing to achieve with standard decor techniques.Effective production procedures are necessary for translating the ingenious designs developed in the area of in-mold decors right into top quality finished products that fulfill market demands and consumer assumptions. Using personalization alternatives such as customized layouts, shade variants, and textural aspects can dramatically enhance the charm of in-mold decor products.

Report this page